The Semiconductor Industry and Its Challenges in Process Control

Description of the Semiconductor Industry

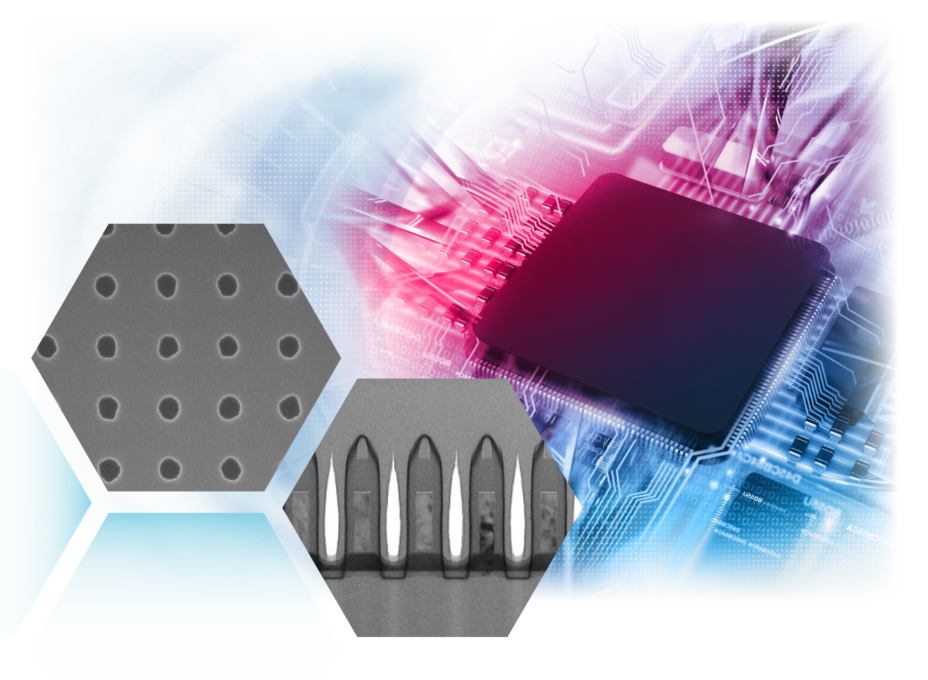

The semiconductor industry is one of the most dynamic and strategically important technology sectors of our time. It underpins nearly all modern technologies: smartphones, computers, embedded systems, autonomous vehicles, medical devices, and much more. This industry designs, manufactures, and distributes integrated circuits (electronic chips) that are essential for technological innovation and the global economy.

Semiconductor manufacturing relies on extremely complex processes, with production lines requiring controlled environments known as clean rooms to avoid contamination. Key steps include lithography, thin film deposition, chemical etching, doping, metrology inspection, and final assembly. These processes must be executed with nanometric precision to ensure the reliability and performance of the produced chips.

Challenges in Process Control

Process control is crucial to ensure efficiency, quality, and yield in semiconductor manufacturing. Here are the main challenges the industry faces regarding process control:

1. Extreme Miniaturization

Semiconductor devices are becoming smaller and more complex, following Moore’s Law, which predicts the doubling of transistors on a chip every two years. Today, manufacturers are producing chips with 5 nm, 3 nm, and soon 2 nm technology nodes. This extreme miniaturization requires nanometric precision, making process control and defect detection particularly challenging.

Solution: The use of advanced metrology techniques and AI-driven control systems helps identify and correct defects at a sub-nanometric scale.

2. Complexity of Manufacturing Processes

Each chip may require hundreds of manufacturing steps. Processes include Extreme UV (EUV) lithography or multiple lithography steps, advanced material applications, and complex etching techniques. Variability at each step can lead to manufacturing defects.

Solution: Real-time process control systems supported by machine learning algorithms and data fusion allow for continuous monitoring and dynamic adjustments of production parameters to minimize variations.

3. Increasing Data Volumes

As manufacturing processes become more complex, the amount of data collected increases exponentially. Each wafer produced generates gigabytes of data from sensors, control equipment, and metrology systems.

Solution: Utilizing big data analytics platforms and artificial intelligence makes it possible to process and analyze these vast data volumes to identify trends, predict failures, and optimize yields.

4. Reducing R&D and Production Cycle Times

Competitive pressures push manufacturers to shorten development timelines for new products while maintaining high quality standards. The development of new processes must be fast and efficient.

Solution: Collaborative process control platforms accelerate the development and deployment of control solutions. AI enables the modeling and simulation of production scenarios to anticipate challenges and reduce R&D cycles.

5. Maintaining Quality and Yield

Even microscopic defects can lead to the failure of an entire chip, reducing production yield. As processes become more complex, maintaining high yields becomes increasingly difficult.

Solution: Predictive control and continuous process optimization via AI help identify problems before they occur, ensuring stable production and consistent quality.

6. Next-Generation Technologies

The arrival of emerging technologies such as quantum computing, 3D devices, and advanced materials (e.g., graphene or compound semiconductors) adds additional layers of complexity to process control.

Solution: Developing new metrology techniques and quickly adapting control algorithms are essential for these disruptive technologies.

Conclusion

The semiconductor industry faces unprecedented technical challenges in process control. By integrating artificial intelligence, advanced metrology, and real-time data processing technologies, companies can optimize their manufacturing processes, improve yields, and ensure high-quality products. Pollen Metrology, with its innovative solutions, plays a key role in helping the industry tackle these challenges and transition to the era of Industry 4.0.